Journalism

[Air sisa plastik] Penggunaan mesin lipatan skru perlindungan alam sekitar Dawei dalam air sisa enapcemar granulasi plastik

2023-01-14

Plastik boleh dilihat di mana-mana dalam kehidupan kita, dan nampaknya telah menjadi bahagian yang sangat diperlukan. Plastik biasa dalam kehidupan seharian termasuk beg membeli-belah pasar raya, beg pembungkusan, mainan, alat tulis, kasut plastik, bampar kenderaan, botol minuman, botol plastik, kotak plastik, tong plastik, sungkupan pertanian, dll.

(Produk plastik)

Kebanyakan produk plastik dibuang sesuka hati selepas digunakan, menyebabkan pencemaran serius kepada alam sekitar semula jadi. Dan plastik boleh kekal di alam semula jadi selama 200-400 tahun. Malah beg plastik terurai mesra alam yang digunakan di pasar raya besar boleh disimpan dalam alam semula jadi selama sekurang-kurangnya sepuluh tahun. Bagi mengurangkan "pencemaran putih" ini, selain mengurangkan penggunaan produk plastik pakai buang, plastik boleh dikitar semula, dikilang semula dan digunakan semula. Pembutiran plastik ialah proses pemesinan plastik.

(White pollution)

Plastic granules are widely sold, and can be used to manufacture various buckets, toys, furniture, stationery, clothing, buttons and other living appliances in daily life; Building materials can be used to manufacture various building tools, doors and windows; In agriculture, it can be used to make agricultural film. With less investment, short payback period, quick return and rich profits in the production chain of recycled plastic granulation, many plastic granulation plants were born under the support of national tax preferential policies and loan preferential policies. The following waste water from plastic granulation has become a concern for environmental protection. Let's take a look at the application of Dawei environmental protection screw folding machine in plastic granulation wastewater.

(Plastic particles)

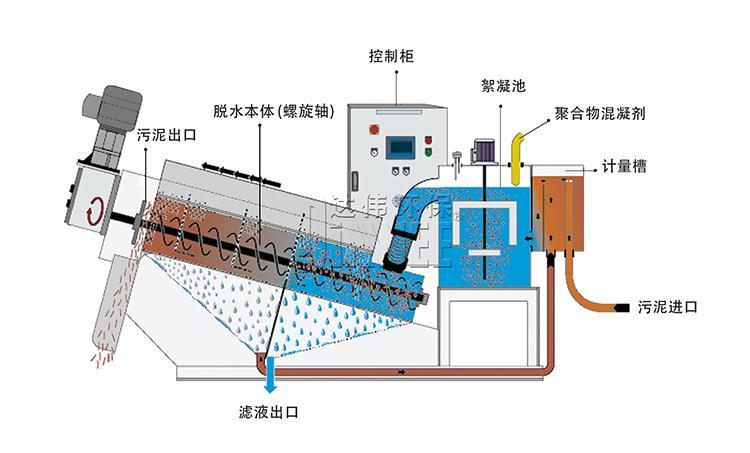

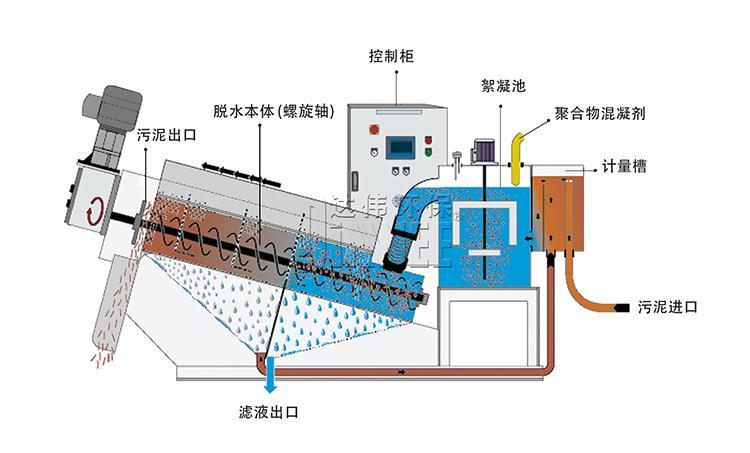

Working principle of the screw type sludge dehydrator: the screw type sludge dehydrator is specially designed for handling low concentration sludge and oily sludge. It follows the principles of force and water in the same direction, thin layer dewatering, proper pressure application and extended dewatering path. It solves the technical problems of previous generations of sludge dewatering equipment, such as easy blockage, inability to handle low concentration sludge and oily sludge, high energy consumption, and complex operation, and achieves the goal of high-efficiency and energy-saving dewatering.

When the equipment is running, the sludge enters the filter cartridge from the feeding port and is pushed to the discharge port by the spiral shaft blades. As the screw pitch between the spiral shaft blades gradually decreases, the pressure on the sludge also increases, and the sludge begins to dehydrate under the effect of differential pressure. The water is self-cleaning between the fixed ring and the movable ring, and the filtering gap is cleaned to prevent blockage, The mud cake is fully dehydrated and discharged from the discharge port under the propulsion of the spiral shaft.

Let's take a look at the sludge treatment process of plastic granulation wastewater:

(Flocculation)

(Sludge discharge)

(Sludge discharge)Actual case application site:

Taizhou Jiangyan XX Plastic Products Factory:

Customer industry: plastic granulation wastewater

Nature of sludge: raw sludge

Model peralatan: mesin lipat skru DW-301, peranti dos DWP-2-500

Anhui Fuyang XX New Material Co., Ltd.:

Industri pelanggan: air sisa granulasi plastik

Sifat enapcemar: enapcemar biokimia

Model peralatan: mesin lipat skru DW-302, mesin lipat skru DW-304, peranti dos DWP-3-1000

Berita Terkini

Kenalan

Telefon setelah jualan negara: 086-523-88858618

Sales hotline:8618052658218

Email: info@diawee.com

Alamat: No. 385 Renmin South Road, Luotang Street, Jiangyan District, Taizhou City, Jiangsu Province