Journalism

Pemilihan saiz dan struktur penyahhidrat susun skru

2021-11-08

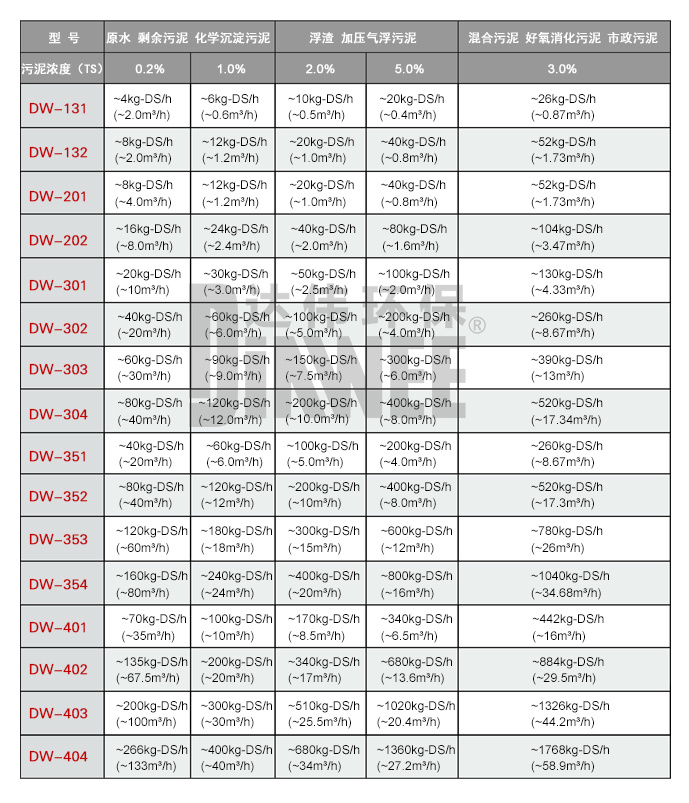

Dehidrator siput bertindan Dawei dilengkapi dengan badan siput bertindan yang direka khas, yang mempunyai reka bentuk yang sangat indah dan mempunyai pelbagai model produk, daripada dehidrator super kecil dengan kapasiti pemprosesan 0.5kg-DS/j kepada dehidrator super besar dengan kapasiti pemprosesan 1320~1360kg-DS/j. Julat saiz antara 1920mm * 75mm * 989mm untuk penyahhidrat kecil hingga 5300mm * 3180mm * 2400mm untuk penyahhidrat yang besar. Dapat memberikan penyelesaian teknikal yang paling sesuai mengikut keperluan kapasiti pengendalian sebenar pelanggan.

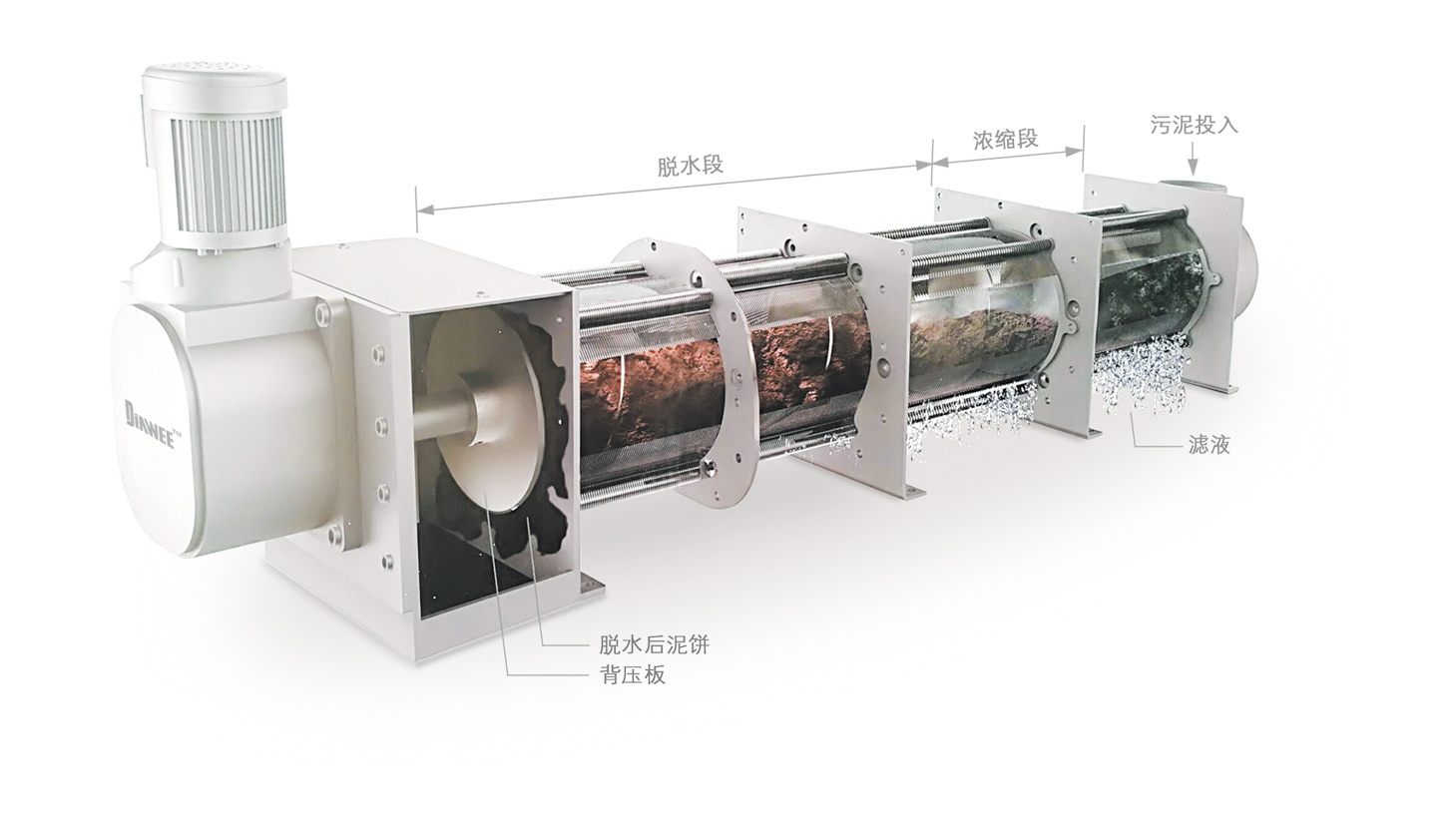

The screw stacking dehydrator consists of metering tank, sludge pump, flocculation mixing tank and dehydration main body. The dehydration process is fully automated by the electric control cabinet (or PLC), which is linked with the dosing equipment and sludge conveying equipment to achieve 24-hour automatic operation. The main body of the dehydrator is composed of a moving ring, a fixed ring and a spiral shaft. There is a movable ring in the middle of every two fixed rings, which increases the overlap, and the lead screw shaft passes through it.

The mixed liquid flows into the filter cartridge of the screw stacking dehydrator through the feed port, and the filter cartridge is composed of fixed laminations and movable laminations alternately. Driven by the spiral shaft, the material moves towards the end of the discharge opening. As the screw pitch between the spiral shaft and the blade gradually decreases, the pressure on the sludge gradually increases. Under the effect of differential pressure, the sludge begins to dehydrate, and the free water flows out from the filter gap between the movable plate and the fixed plate.

As the diameter of the spiral shaft is larger than the diameter of the movable plate, when the spiral shaft rotates, it drives the movable plate to rotate together. The dehydrator relies on the relative movement of the movable plate and the fixed plate to realize the self-cleaning function and prevent the filter gap from being blocked. The completely dehydrated mud cake is discharged from the discharge port under the push of the spiral shaft. Since there is always relative movement between the fixed plate and the movable plate, some small sludge particles are always squeezed out of the gap with water.

In order to prevent overflowing sludge particles from depositing on the surface of the filter cartridge, an automatic water spraying washing system is set up to spray clean the surface of the filter cartridge regularly to keep the surface of the filter cartridge clean. The obtained mud cake has a moisture content of 78% - 85%, a solid recovery of more than 95%, a screw shaft speed of 2-3 r/min, no vibration, no noise, and can be directly dehydrated at low temperature.

Air keluar pengekstrak skru mempunyai kekeruhan tertentu. Apabila air yang ditapis kembali ke sistem biokimia, turasan dibenarkan mempunyai kekeruhan tertentu. Kelegaan antara plat tetap dan plat alih ditetapkan di kilang dan tidak boleh dilaraskan sesuka hati. Kandungan air kek lumpur penapis boleh dilaraskan dengan melaraskan kelegaan plat tekanan belakang dan jumlah suapan.

Dehidrator siput bertindan Dawei mempunyai keluasan lantai yang kecil, pembersihan sendiri, tidak tersumbat, tiada bunyi bising, penggunaan tenaga yang rendah, automatik sepenuhnya tanpa pengawasan, stabil dan boleh dipercayai, menjimatkan kos infrastruktur, julat aplikasi yang luas, dan lebih baik dalam mengendalikan enap cemar berkepekatan rendah. Mengalu-alukan pelanggan untuk bertanya!

Berita Terkini

Kenalan

Telefon setelah jualan negara: 086-523-88858618

Sales hotline:8618052658218

Email: info@diawee.com

Alamat: No. 385 Renmin South Road, Luotang Street, Jiangyan District, Taizhou City, Jiangsu Province